By Michael Longley, Managing Consultant at Food Chain Enterprises Ltd.

By Michael Longley, Managing Consultant at Food Chain Enterprises Ltd.

Introduction

The Global Covid-19 pandemic has had far reaching consequences for the agricultural industry. One of the biggest and most immediate effects for the poultry industry has been the closing of the food service sector, almost overnight. This followed by a prolonged period of uncertainty and further restrictions on the hospitality sector, has led to Global issues of supply and demand. Producers have had huge challenges of how to re-distribute product destined for the food service industry to other markets. Constant adjustments to bird numbers/placements and product mixes have been necessary in response to continued market upheaval as the pandemic has progressed.

Secondary to this, is the impact of the pandemic on the industry’s ability to staff itself and look after employee welfare. Nowhere has this been more apparent than in processing plants where the lack of social distancing, the environment and working processes are conducive to the rapid spread of Covid. So, what steps should processors take to keep the production line running, their staff safe and a continued supply of grade A product?

Processing and Covid

Despite excellent hygiene practices being in place, the environment within a processing plant makes them ideal places for the rapid spread of Covid: lower temperatures and very high or very low humidities, are conditions that the virus is known to thrive in; high volumes of metallic surfaces are known to retain live viruses for longer; and workers often speak loudly or shout over the noise increasing the spread of droplets,. Processing plants have been working extremely hard in recent months to overcome the issues with operating under extreme social distancing restraints and government Covid guidelines, for safe operating procedures.

Socially distanced processing

The bird shackling area or hang-on is the start of the processing production line. It is an area that is already heavily monitored both for human and bird welfare and the use of face masks and visors has been in place for some time. However, for protection against Covid, masks and visors need to be of a heavier duty standard, and it may be necessary to upgrade the masks worn in the shackling area. Ventilation levels should be increased to ensure maximum air flow at all times and a 2-metre distancing rule between hang-on operatives should be implemented if one is not already in place.

In the kill, scald, defeather and EV areas, where the number of operatives is generally lower, social distancing, face visors and masks should be compulsory. In cut-up / portioning areas operatives should be socially distanced, with either head height plastic panels or heavy strip curtains between each operative. This is particularly important at key points where traditionally there would be a high number of operatives present (e.g. thigh / leg de-bone).

In the packing and dispatch areas extra space should be made available where possible, by reducing the amount of personnel / vehicular traffic and introducing a one-way system to allow for social distancing continued smooth movement of product. All operatives should wear face masks.

All areas of the processing plant should have increased cleaning and disinfection protocols in place and all operatives should apply enhanced personal hygiene practices in line with Government guidelines.

Prior to anyone entering the processing plant, body temperature should be recorded using a reliable infrared or temporal lobe thermometer. Anyone with a higher than normal reading should be sent home immediately to self-isolate.

Any ‘public’ areas such as canteens or break rooms where a large number of employees from all areas of the plant would normally gather, must be heav- ily controlled with social distancing in place. This necessitates split break times, and one-way movement systems. Face masks must be worn unless eating is taking place and eating alone rather than in groups should be implemented. Toilet and changing areas must also have social distancing rules and a one-way system in place. Staggering shift start and finishing times will help minimise the maximum number of people congregating in ‘public’ areas at any one time and help maintain social distancing rules.

The introduction of so called “Covid Marshals” to supervise workflows, “marshal” the new normal, and monitor adherence to any protective measures in place is an essential part of maintaining a safe working environment and employee welfare.

What of the birds?

While the implementation of protective measures for staff has been essential to allow continued production and supply of poultry meat, let’s not forget the birds themselves. Good welfare practices from catching to processing are essential; without a quality product to process there is no processing to be done. And although the current working environment is difficult for all areas of the poultry industry bird welfare remains as always, a top priority for the entire industry. What are the key points to consider?

Coordination is key

Management of the logistics of getting the birds from the farm to the processing plant is important to ensure birds arrive at the plant in good condition and minimise the time in lairage. Coordination and communication between a number of different areas is necessary:

• Farm and processing plant – to establish processing time and therefore the timing of feed withdrawal and to avoid excessive lairage times and contamination through full crops and intestines.

• The farm and the catching team – to ensure correct feed withdrawal and timely and efficient catching to fit in with processing times.

• Truck drivers – to ensure birds are loaded and transported to the plant to arrive at the correct time and in good condition.

Preparation for catching

Keeping birds calm during the catching process is a key aim of any producer. While there are several different ways this can be achieved, the first step starts up to 3 days before catching when light should, where possible, be increased to 23 hrs of light a day.

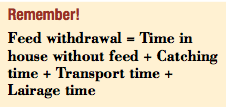

The next step in the build up to catching is feed withdrawal. The aim of feed withdrawal is to empty the gastrointestinal tract (GIT) of all feed prior to processing. This reduces the risk of faecal contamination during transportation and at the processing plant.

Time without feed before processing (feed withdrawal time) is normally between 8 and 12 hours but this is dependent on environmental temperatures. Feed withdrawal time should be monitored routinely. If it is too long, there will be increased weight loss from the carcass with implications for profit through lost yield and bird welfare. If it is too short, there will still be feed left in the GIT at processing which increases the risk of faecal contamination of the carcass, contamination with partially digested feed from intestines, gizzards and crops, and carcass downgrades.

Unlimited water should be provided until the point of catching to avoid dehydration. Ventilation must be carefully controlled during catching to avoid chilling or over-heating. It is important to keep fresh air owing during catching, for the welfare of both the birds and the catchers.

Catching

Catching should be done by competent/ trained personnel and ideally done at night when temperatures are generally lower and light intensity can be kept to a minimum to keep the birds calm.

Local legislation for the number of birds per crate/module should be followed in all circumstances. Overcrowding in crates will lead to over-heating, poor bird welfare, increased mortality, and increased condemnations at the processing plant. The number of birds per crate should be reduced in summer or at hotter times of the year. It is difficult to say by how much bird numbers should be reduced, but temperature, size of birds, the size of the crate and local legislation must all be considered.

Transport

Birds can quickly become over-heated in hot weather when the transport vehicle is stationary. If it is hot the use of fans during loading can help keep birds cool until loading is finished. Adequate spacing around the crates on the lorry will improve air movement around the birds during transportation. The transport route and time to the processing plant should be as short as possible with minimal stops.

Lairage

Lairage for the birds should be suitably lit, blue lights are ideal to keep bird’s calm. Appropriate shade and fans for ventilation, should be in place to minimise bird stress and prevent over-heating. In hot weather high-pressure water fogging equipment may be required to ensure bird comfort prior to processing.

Stunning and slaughter process

Blue light in hang-on areas will help keep bird’s clam prior to slaughter. Comfort bars at breast level once the birds have been hung will also help in this respect. Stunning & slaughter procedures must be well-managed to ensure birds are effectively stunned & dispatched and regular, routine checks of the stunner are essential.

What will the future be?

Initial impacts of the pandemic to the production line, now seem to have been resolved and alternative sales routes utilised, many plants are running back to pre-COVID-19 capacities, while still adhering to strict Covid safety guidelines. Making sure your staff are comfortable and have a comfortable working environment will help their motivation as well as create an environment that encourages positive bird treatment and care. The pandemic is still very much with us and it seems likely that newly installed prevention measures and daily working protocols will remain in place, well into the future.