Eduardo Costa, Hatchery Specialist,

Cobb World Technical Support Team

Transfer management is one of the most delicate and important tasks at the hatchery. At the same time, it needs to be efficient and smooth.

When eggs are transferred from a setter, they go from an upstanding position to a lateral position once they are placed in the hatcher. This will allow the chick to move can be single or multi-stage, but all the eggs will ultimately be transferred to a single-stage hatcher.

Putting the eggs in a different environment for hatch (all in – all out) is important for hygiene because hatching generates a lot of residue and chick down, which may promote the spread of contamination.

The single age chamber allows for managing a temperature step-down program to avoid overheating and dehy during and after hatch. The setters drating the chicks, which helps maintain good chick quality.

At transfer time, the egg shell is very fragile due to the utilization of part of the calcium for skeleton development, thus making the egg vulnerable to transfer cracks. When the eggs crack during transfer, the egg will dehydrate and the internal membrane will stick to the baby chick—disrupting the movements of the bird and hatch. If the transferring is too rough, it can immediately kill the embryo by mechanical damage.

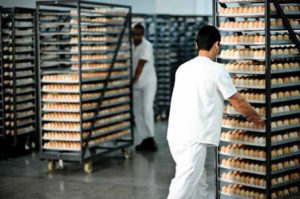

When using manual transfer, the team needs to be carefully chosen and thor oughly trained. The physical attributes of the team need to be compatible with the task. For example, if a shorter person tries to place a tray on the top position of the trolley, he/she will probably incline or tilt the tray. When this occurs, the eggs will roll to the lower end—cracking a significant amount of eggs. When transferring together, both people need to be roughly the same height; otherwise, the tallest person will be in a very uncomfortable position, compromising the synchronization of the work.

If transfer takes too long, the eggs will cool down, ultimately delaying hatch and disturbing the hatch window. The time between the eggs leaving the setter and entering the hatcher needs to be less than 20 minutes.

Make sure everything is ready before you start transferring – we don’t want to realize that we are missing a spread sheet or the transfer machine is not ready when the eggs are already in the transfer room. This will delay transfer and cool down the eggs.

Make sure everything is ready before you start transferring – we don’t want to realize that we are missing a spread sheet or the transfer machine is not ready when the eggs are already in the transfer room. This will delay transfer and cool down the eggs.

Single-stage incubators must stay running until the last egg is pulled out of the machine. The hatcher baskets need to be washed, disinfected, dried and warm for transferring. The hatcher also needs to be dry; otherwise it will lose control of humidity and temperature.

If eggs are transferred to wet trays, then they will quickly cool down. The hatchers should be turned on at least two hours before transfer with the trolleys and trays inside; this will warm the equipment and also help in drying the machine and trolleys.

Hatch is a difficult task. When the chick emerges from the egg, it’s still wet and very tired. At this moment, its navel is not completely healed and it’s sitting directly on the tray while recovering from hatch. This is why it’s so important to have the trays clean and disinfected before transfer.

Candling 100% of the trays and removing all ‘clear’ eggs (infertile and early dead) is recommended. If chick processing is done by an automatic chick separator, this practice becomes obligatory. Candling and removing the clear eggs allows more space in the hatcher basket, which results in better ventilation and cleaner chicks, and reduces the liquid content of the eggshell residue.

Replacing the empty spots on the tray after candling is not recommended; doing this will concentrate too many viable embryos on a tray and/or hatcher and overheating will be likely to occur. If manually candling, always be conscious of the time so that you can avoid cooling the eggs.

Periodically make a sample of the ‘clear eggs’ from young, prime and old flocks and break to check the accuracy of the personnel or machines. The candling results can be used to predict hatch.

All ‘exploder’ eggs should be removed and disposed of on a receptacle with disinfectant.

Extreme care needs to be taken to prevent these eggs from exploding before they hit the disinfectant solution.

Removing these eggs prevents a large risk of contamination, so great care must be taken. Start transfer with the young or less contaminated flocks, leaving the ‘risky’ flocks until the end of the procedure.

When using automatic transfer, special care needs to be taken on the hygiene of the transferring suction cups and tweezers to avoid cross-contamination.

In ovo vaccination is a great technology that is popular in the poultry industry. It consists of injecting the vaccine inside the egg (in the amniotic fluid or the embryo) at transfer time. For this to happen properly, it needs to be done at the right time and the embryo needs to be in the correct position.

Vaccinating upside down eggs will kill most of the embryos. In ovo gives earlier immunity for the embryo, less chance of personal errors, less need for labor, less chick handling and faster access to feed and water. Unfortunately, this technology is not compatible with killed vaccines (oil emulsions).

Follow the in ovo manufacture recommendations carefully, especially for the cleaning cycles before and after vaccination. Transfer age is very important.

It’s quite common to find that with plants hatching on Monday and Tuesday the hatch is lower when compared to Thursday and Friday. Normally, this occurs because the hatchery is avoiding the transfer of eggs on the weekend due to labor and ends up transferring the eggs of these hatches too early or late.

If vaccinating the eggs before 18 days or after 19 days, there is a higher chance of vaccinating in the improper site of injection, reducing hatch and chick quality. At in ovo vaccination, we want to have less than 1% of external pipped eggs.

The best results are observed when eggs are transferred between 18 and 19 days. If you are not doing in ovo vaccination, transfer can be done a little earlier, but adjustments will need to be made to the hatcher temperature.

Egg transferring is a necessary procedure for every hatchery and creating well-defined procedures and controls for egg transferring will help to maximize hatchability, chick quality, and improve broiler performance and overall reduce cost. they hit the disinfectant solution.